Keep Your Production Moving with Collaborative Robots

The need for adaptable, efficient automation continues to grow across every industry. Collaborative robots (cobots) boost productivity and workplace safety by working directly alongside your team, managing repetitive or strenuous tasks without interrupting your processes.

At Custom Fluid Power, we help manufacturers harness the full potential of cobot technology. Our experts design and integrate scalable automation systems for applications such as machine tending, assembly, and more. Whether you’re optimizing existing workflows or launching a new automation initiative, cobots offer rapid ROI and lasting performance improvements.

Transform Productivity with Collaborative Robots

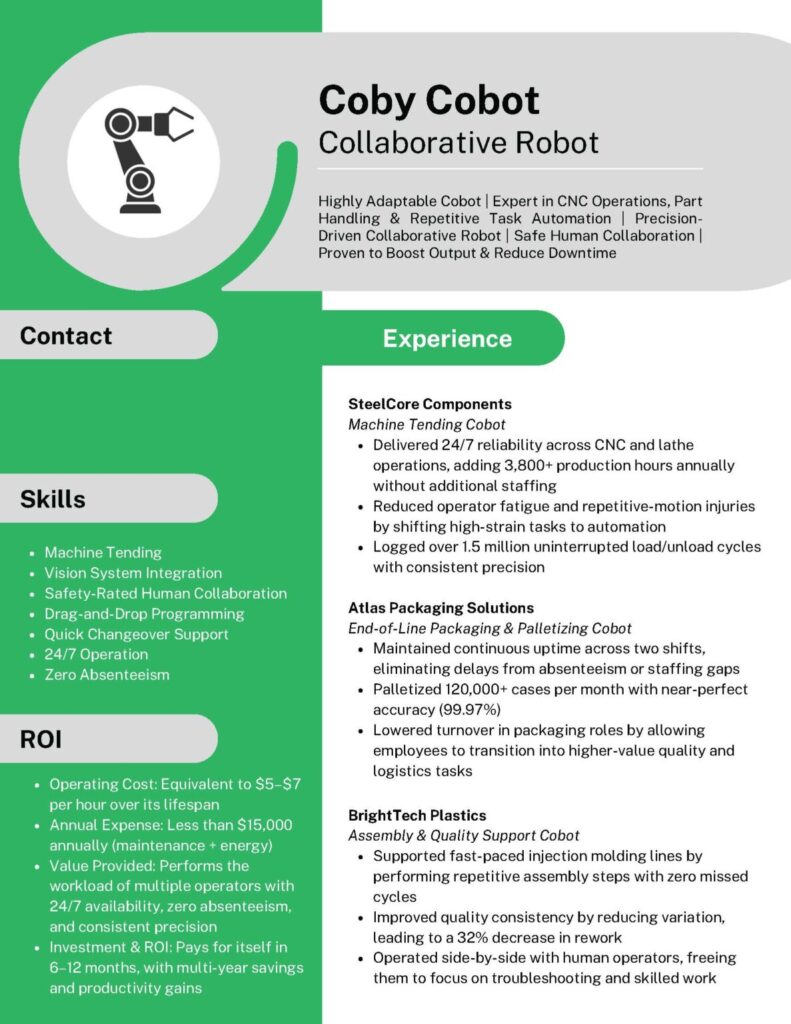

Your Most Dependable Team Member

Cobots are a new generation of robots built to work safely alongside people. Unlike traditional industrial robots that require cages or safety barriers, collaborative robots are designed for direct human interaction on the production floor. They’re intuitive, adaptable, and ideal for repetitive, physically demanding, or hazardous tasks.

By addressing today’s biggest operational challenges—such as rising labor costs, safety concerns, and production delays—cobots help manufacturers improve output, enhance workplace safety, and operate more efficiently.

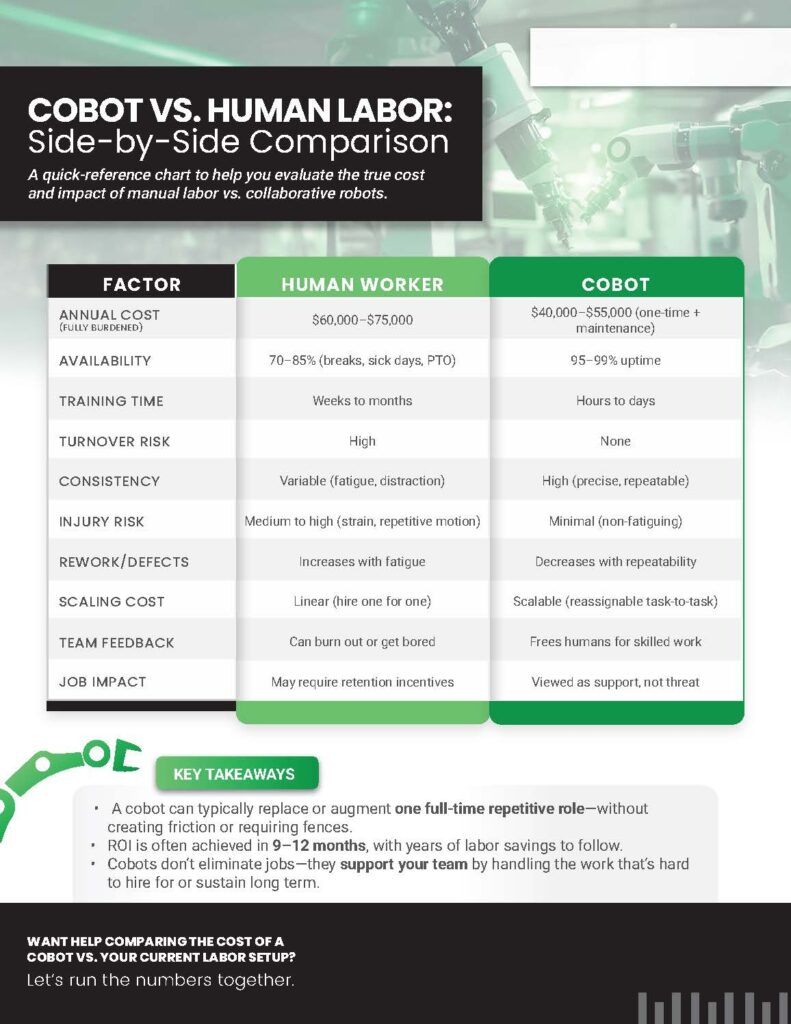

Uncover the True ROI of Automation

Investing in cobots delivers more than automation—it delivers measurable results. Businesses implementing cobots see fast returns through lower labor costs, reduced downtime, and increased productivity. The upfront investment pays off quickly, freeing teams to focus on higher-value work.

Reduce Labor Costs

Quick Deployment, Fast ROI

Flexibility on the Floor

Enhance Workplace Safety

Boost Efficiency & Throughput

Empower Your Workforce

Estimate Your Cobot Investment and Payback — Start the ROI Calculator

See Cobots in Action

Collaborative robots close the gap between manual processes and full automation, giving manufacturers a flexible, cost-effective way to overcome challenges like labor shortages, rising costs, and quality control issues.

Cobots deliver precision, consistency, and scalability, helping your team work smarter, not harder. They enhance efficiency across a wide range of applications while keeping production running smoothly.

Explore the key ways cobots can streamline your operation and support long-term performance.

Machine Tending

Cobots handle machine loading and unloading with precision, improving efficiency and consistency while reducing operator fatigue and downtime.

Palletizing

Cobots stack products or materials with accuracy, minimizing manual labor and maintaining steady throughput in high-volume operations.

Pick and Place

Cobots move components quickly and precisely between stations, streamlining production and ensuring consistent part handling.

Assembly

Cobots perform repetitive assembly and fastening tasks with accuracy, helping increase production speed while reducing human error.

Hazardous Environments (C1D1)

Cobots safely operate in C1D1 areas, handling hazardous materials or processes that would otherwise endanger human workers.

Welding

Cobots deliver precise, consistent welds for spot and arc applications, ensuring high quality across small-batch and custom production.

Lab Automation

Cobots support lab workflows by automating sample handling and testing, improving accuracy and freeing staff for complex tasks.

Inspection

Cobots equipped with vision systems detect product defects and inconsistencies, improving quality control and reducing rework.

Cobots from Trusted Industry Leaders — Powered by Custom Fluid Power

Custom Fluid Power partners with leading collaborative robot manufacturers to deliver reliable, high-performance automation solutions. Through strategic relationships with innovators like Standard Bots and Mitsubishi Electric Automation, we provide access to advanced cobot technology suited for any application or budget.

Our team helps manufacturers realize the full potential of collaborative automation with complete, turnkey solutions. From design and integration to training and ongoing support, Custom Fluid Power ensures every system is deployed efficiently and performs at its best from day one.

Standard Bots

Experience American-made cobots built for quick setup, simple programming, and flexible deployment, making automation easier to adopt and scale.

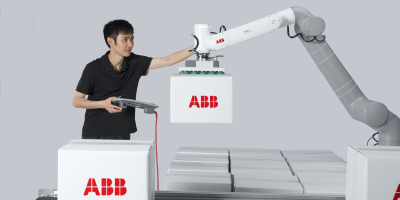

ABB

Enhance your production with ABB’s advanced collaborative robots, known for precision, durability, and intelligent control, making them ideal for demanding industrial environments.

Robotics Just Got a Major Tax Advantage

On July 4, 2025, Congress passed H.R. 1 (Public Law 119-21), reinstating 100% first-year bonus depreciation for qualified production equipment. That means robotic systems—including cobots—can now be fully deducted in year one, helping manufacturers accelerate ROI and strengthen their bottom line faster than ever.

Cobot Knowledge Hub

Stay informed with the latest advancements and best practices in collaborative robot. Click on the resource to start your download.

Your Cobot Questions, Answered

A cobot is built to safely share workspace with humans without needing safety cages or barriers. It’s smaller, easier to program, and more cost-effective to integrate into production than a traditional robot.

Yes. Cobots are engineered with advanced safety systems, including force-limiting sensors, emergency stop features, and motion controls that slow or stop automatically when people are nearby.

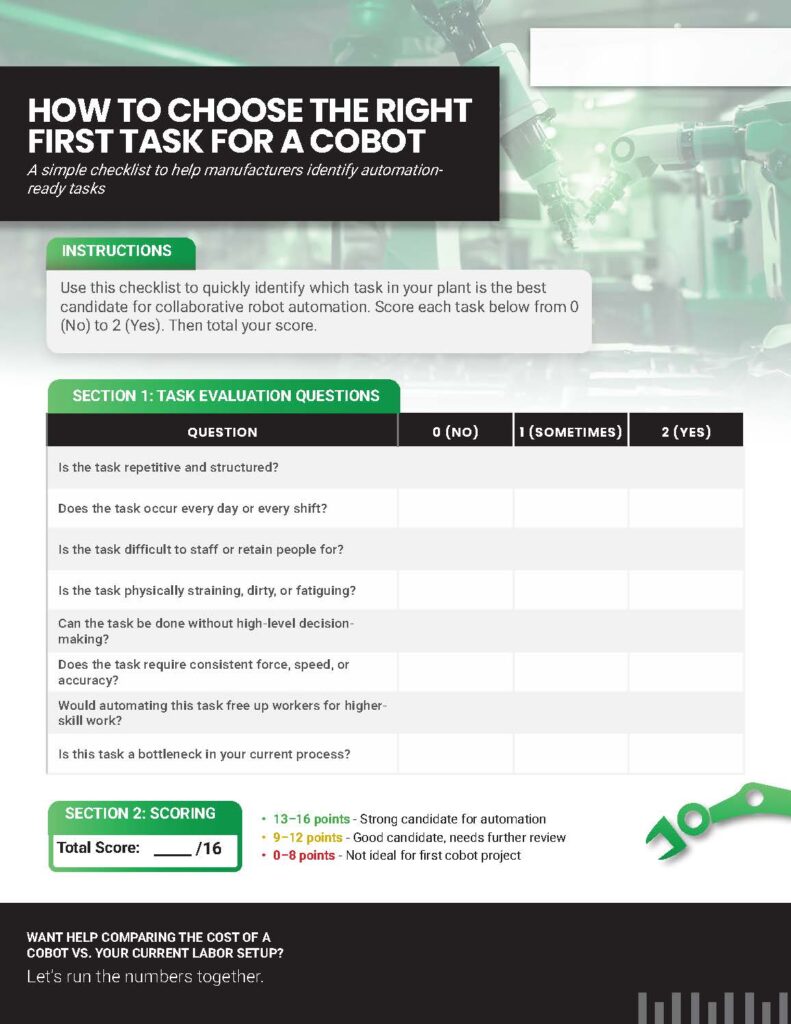

Start by defining the tasks you need to automate, the payload and reach required, and your budget. Then, evaluate which cobot best aligns with your goals for speed, flexibility, and ease of programming.

Most cobot systems can be installed and running within days, not months. Custom Fluid Power’s integration team delivers turnkey setup and hands-on training to get your operation up to speed quickly.

Cobots are widely used in manufacturing, packaging, metalworking, electronics, and food and beverage, along with many other sectors where efficiency, precision, and safety are top priorities.

Yes. Most cobots are lightweight and portable, making them easy to relocate and reprogram for new tasks—perfect for dynamic or small-batch production environments.